Crude Cottonseed Oil Refinery Plant

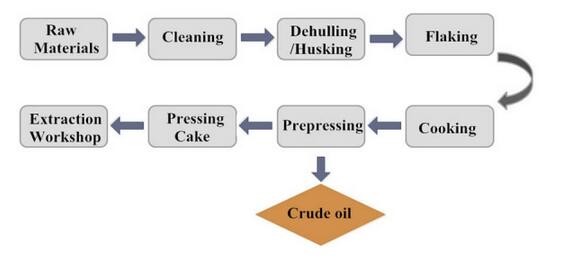

Cottonseed Oil Extraction Processing

Degumming

Phospholipids are easy to adsorb bleaching clay and reduce bleaching effect. Meanwhile, the gossypol in the crude oil can react with phospholipids to form bound gossypol which can’t be removed. By degumming, the filtered cottonseed oil is preheated and phosphoric acid is added to change nonhydratable phospholipids into hydratable phospholipids.

De-acidification

Cottonseed oil is mixed with alkali which reacts with free fatty acids to form soapstocks. The mixture is centrifuged to separate the soapstocks from oil. The soapstocks have strong adsorbability and can adsorb some pigment, protein, phospholipids, mucilage and other impurities. The free gossypol also reacts with alkali to form the salt, which is adsorbed on the soapstocks to be removed. The oil is washed with hot water to remove the residual soapstocks. The wastewater is separated from the oil in a second centrifuge. The oil is then dehydrated under vacuum.

Bleaching

The degummed and neutralized oil is mixed with bleaching earth and then the mixture is sent into the bleaching tower in the cottonseed oil refinery plant. By heating under vacuum, the residual gossypol and other pigments in the oil are adsorbed on the clay. The mixture from the bleaching tower is pumped into the leaf filter to remove the waste clay.

Deodorization

The bleached oil is pumped into the deodorization tower in the cottonseed oil refinery plant to remove the free fatty acids and odor substances so that to improve the flavor, stability, color, and quality of the oil. The deodorization process is performed under high temperature and high vacuum.

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Mustards are part of the oilseed family and are regarded both as a s...

Interested in begin a small size corn oil extraction plant but dont ...

Do you want to make the edible rice bran oil at from using your mill...