palm oil refinery

Palm oil is a common cooking ingredient in the coutries and areas of tropical belt. The use of palm oil in food products is often the focus of environmental activist groups, due to it being documented as a cause of substantial and often irreversible damage to the natural environment. Palm oil refinery, however, is a complicated process. If you use palm oil for edible uses, you will need to refine the oils to get quality palm oil.

Palm Oil Refinery

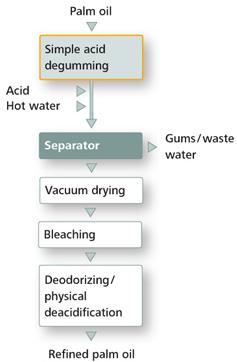

There are some main procetures for palm oil refinery you should follow and we will describe it in detail.

Crude palm oil (CPO) from the CPO storage tank. CPO is feed at the flow rate about 35-60 tons/hour. The initial temperature of CPO is at 40 – 60°C. The feed is pumped through the heat recovery system, that is plate heat exchanger to increase the temperature around 60 – 90°C. After that, there is about 20% of the CPO feed to into the slurry and mix with the bleaching earth (6 – 12kg/ton CPO) to form slurry (CPO + Bleaching earth). The agitator inside the slurry tank will mixed the CPO and bleaching earth completely. Then, the slurry will go into the bleacher. At the same time, another 80% of the CPO is pumped through another plate heat exchanger (PHE) and steam heater to increase the CPO temperature to 90 – 130°C (it is a desired temperature for the reaction between CPO and phosphoric acid). Then, the CPO feed is pumped to static mixers and the phosphoric acid is dosed at 0.35 – 0.45 kg/ton. Inside there, the intensive mixing is carried out with the crude oil for precipitation up the gums. The precipitation of gums will ease the later filtration process, avoid the scale formation in deodorizer and heating surface. The degumming CPO then will go into bleacher.

In the bleacher, there are 20% slurry and 80% degummed CPO will mix together and the bleaching process occur. The practice of bleaching involves the addition of bleaching earth to remove any undesirable impurities (all pigments, trace metals, oxidation products) from CPO and this improves the initial taste, final flavor and oxidative stability of product. It also helps to overcome problems in subsequent processing by adsorption of soap traces, pro-oxidant metal ions, decomposes peroxides, colour reduction, and adsorbs other minor impurities. The temperature inside the bleacher must be around 100°C – 130°C to get the optimum bleaching process for 30 minutes of bleaching period. The low pressure steam is purged into bleacher to agitate the concentrated slurry for a better bleaching condition. Bleached palm oil (BPO) from Niagara filter is then pumped into buffer tank as a temporary storage before further processing.

A second check filter - trap filter is usually being used to double ensure that no bleaching earth slips occur. The presence of bleaching earth fouls deodorizer, reduces the oxidative stability of the product oil and acts as a catalyst for dimerizaition and polymerization activities. So, the “blue test” is carried out for each batch of filtration to ensure the perfect filtration process. This test indicates whether any leaking is occurring in Niagara filter or trap filter. Hence, any corrective actions can be taken intermediately.

The BPO comes out from the filter and passes through another series of heat recovery system, Schmidt plate heat exchanger and spiral (thermal oil: 250 – 305°C) heat exchanger to heat up the BPO from 80 – 120°C until 210 – 250°C. The hot BPO from spiral heat exchanger then proceeds to the next stage where the free fatty acid content and the color are further reduced and more important, it is deodorized to produce a product which is stable and bland in flavor.

In the pre-stripping and deodorizing column, deacidification and deodorization process happen concurently. Deodorization is a high temperature, high vacuum and steam distillation process. A deodorizer operates in the following manner: (1) dearates the oil, (2) heat up the oil, (3) steam strips the oil and (4)cools the oil before it leaves the system. All materials if contact are stainless steel.

In the column, the oil is generally heated to approximately 240 – 280°C under vacuum. A vacuum of less than 10 torr is usually maintained by the use of ejectors and boosters. Heat bleaching of the oil occurs at this temperature through the thermal destruction of the carotenoid pigments. The use of direct steam ensures readily removal of residue free fatty acids, aldehydes and ketones which are responsible for unacceptable odor and flavors. The lower molecular weight of vaporized fatty acids rises up the column and pulls out by the vacuum system. The fatty acid vapor leaving the deodorizer are condensed and collected in the fatty acid condenser as fatty acid. The fatty acids then is cooled in the fatty acid cooler and discharged to the fatty acid storage tank with temperature around 60 – 80°C as palm fatty acid distillate (PFAD), a by-product from refinery process.

The bottom product of the pre-stripper and deodorizer is being refined, bleached, deodorized palm Oil (RBDPO). The hot RBDPO (250 – 280°C) is pumped through schmidt PHE to transfer its heat to incoming BPO with lower temperature. Then, it passes through another trap filters to have the final oil polishing (120 – 140°C) to prevent the earth traces from reaching the product tank. After that, the RBDPO will pass through the RBDPO cooler and plate heat exchanger to transfer the heat to the CPO feed. The RBDPO then is pumped to the storage with temperature 50 – 80°C.

Who have constantly been upgrading our technology on palm oil refinery and our research and development department has been coming out with innovations and new solutions to address our clients' requirement. We design, manufacture and supply premium palm oil refinery equipment and we also offer customized oil refinery plant for other oilseeds. We are always at your service. Write to us today to know more info!

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Mustards are part of the oilseed family and are regarded both as a s...

Interested in begin a small size corn oil extraction plant but dont ...

Do you want to make the edible rice bran oil at from using your mill...