Edible Oil Cold Press Process

Home > Recent Posts >

Our customers value the quality of our edible oil pressing machinery and the health of their customers. That is why we introduce a Cold Press Process for our customer to produce their edible seed oil. It may take some more time; however, the final product is worth it.

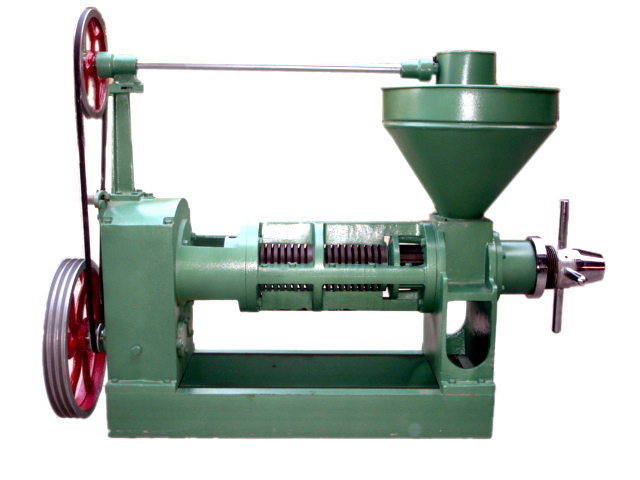

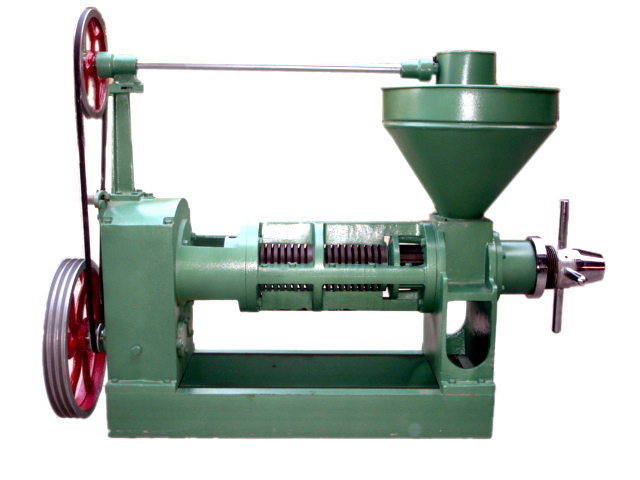

Today, the majority of seed oils are pressed using a Screw Press. The seed goes in the top, is crushed and squeezed in the middle where the oil comes out and the waste is pushed out the end. There is sometimes heat applied from the outside and/or friction can generate an unknown amount of heat as well. In the beginning we offer our customers this method and found that the edible seed oil produced had a low quality flavour, colour and yield.

By using our edible oil pressing machinery through the Cold Press Process to produce seed oil, the result is a natural dark colour, high flavour and strong aroma oil. This Cold Press Process method with 300 years of experience which increases nutrients extracted from the seed and gives a more robust nutty flavour and deeper colour, which shows the quality and proves it have the highest benefits to your health.

The second step is to transfer the 'oil seed mash' into a cylinder with hundreds of tiny holes and simply squeeze with a lot of pressure from both ends. As there is minimal movement no friction or heat is generated during the squeeze. The oil runs through the holes into a collection tank. The 'left over' oil seed body which is made up of concentrated protein, carbohydrate and non-fat soluble vitamins and minerals forms a large 'oil cake'. The oil cake can be used as the stock feed.

You do not need to bleach, deoderise, antifoam or filter your seed oil, it is simply left to sit for a few days in our storage tanks, before bottling, so that any fine particles of oil seed can settle to the bottom. The seed oil is then taken from the top and put into dark glass bottles ready for capping, labeling and delivery to the customers.

Buy our edible oil pressing machinery today and press your own edible oil for your family or sell them to the local market.

For any of question , KMEC - the leading edible oil pressing machinery - is at your service for more information. Contact us in the form following.

Today, the majority of seed oils are pressed using a Screw Press. The seed goes in the top, is crushed and squeezed in the middle where the oil comes out and the waste is pushed out the end. There is sometimes heat applied from the outside and/or friction can generate an unknown amount of heat as well. In the beginning we offer our customers this method and found that the edible seed oil produced had a low quality flavour, colour and yield.

By using our edible oil pressing machinery through the Cold Press Process to produce seed oil, the result is a natural dark colour, high flavour and strong aroma oil. This Cold Press Process method with 300 years of experience which increases nutrients extracted from the seed and gives a more robust nutty flavour and deeper colour, which shows the quality and proves it have the highest benefits to your health.

The Cold Oil Press of KMEC

The first step is to crush and then gently roast the oil seeds at a low temperature prior to pressing by our edible oil pressing machinery. This roasting process increases the flavour of the seed oil and also draws more of the nutrients from the body of the oil seed. The roast is temperature controlled to ensure no over heating or damage to the delicate essential fatty acids contained in the oil.The second step is to transfer the 'oil seed mash' into a cylinder with hundreds of tiny holes and simply squeeze with a lot of pressure from both ends. As there is minimal movement no friction or heat is generated during the squeeze. The oil runs through the holes into a collection tank. The 'left over' oil seed body which is made up of concentrated protein, carbohydrate and non-fat soluble vitamins and minerals forms a large 'oil cake'. The oil cake can be used as the stock feed.

You do not need to bleach, deoderise, antifoam or filter your seed oil, it is simply left to sit for a few days in our storage tanks, before bottling, so that any fine particles of oil seed can settle to the bottom. The seed oil is then taken from the top and put into dark glass bottles ready for capping, labeling and delivery to the customers.

Buy our edible oil pressing machinery today and press your own edible oil for your family or sell them to the local market.

For any of question , KMEC - the leading edible oil pressing machinery - is at your service for more information. Contact us in the form following.

Products

Projects

Recent Posts

mini mustard oil mill

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Want to set up a mini mustard oil mill of your own ? With the rapid ...

mustard oil manufacturing process

Mustards are part of the oilseed family and are regarded both as a s...

Mustards are part of the oilseed family and are regarded both as a s...

small size corn oil extraction plant

Interested in begin a small size corn oil extraction plant but dont ...

Interested in begin a small size corn oil extraction plant but dont ...

rice bran oil project

Do you want to make the edible rice bran oil at from using your mill...

Do you want to make the edible rice bran oil at from using your mill...