rice bran oil project

Home > Recent Posts >

Do you want to make the edible rice bran oil at home from using your milled rice waste? If the answer is "Yes". Congratulations.You get the right page you need. Henan Kingman Mechanical & Electrical Complete Plant Co., Ltd. (KMEC) deals principally in designing, manufacturing , exporting rice bran oil project and related oil processing equipment. We also provide professional customized other edible oilseed oil pressing mill and a variety of oilseed processing services. (Related Equipment: )

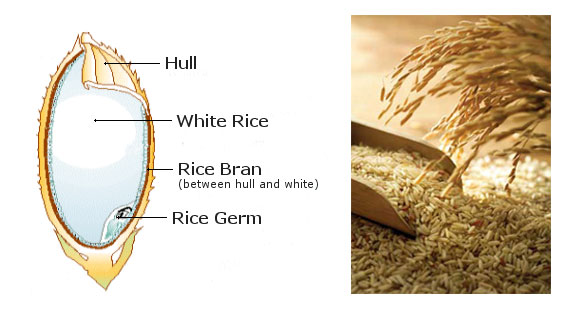

Rice bran is by-product obtained during rice milling operation. This is golden reddish cuticle obtained after removal of the husk and during polishing of the rice.

Rice Bran and Its Structure

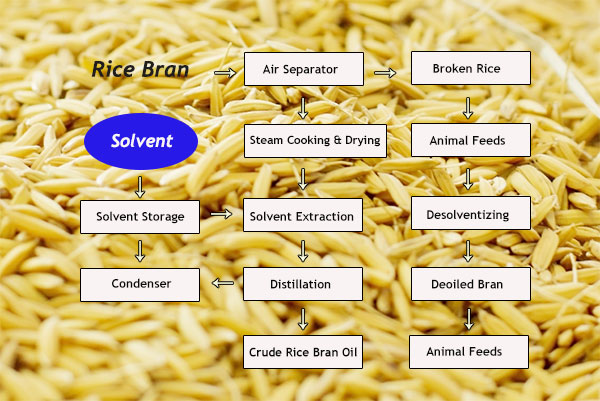

Rice Bran Oil Extraction: You can extract the crude rice bran oil either by mechanical method with oil presses or by chemical method with solvent. After proper preparation, the bran is fully stabilized and sent to an extraction area where oil is removed, yielding two products,a high quality crude rice bran oil and defatted rice bran.

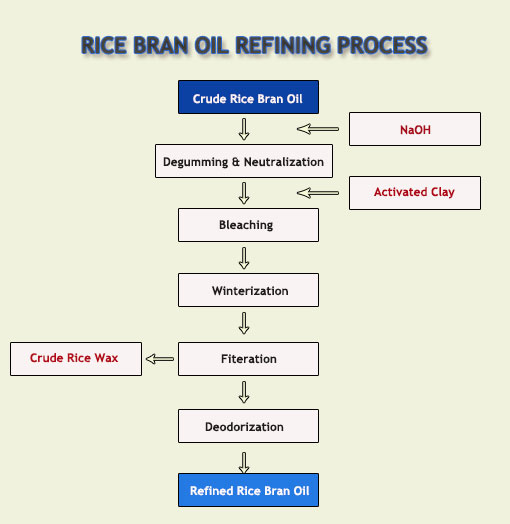

Steam distillation is the final step in the edible oil process and it is here that any off flavors and residual free fatty acids left in the oil are removed. Once the oil has been fully processed, it is ready for packaging into retail bottles, food service pails or bulk drums. Click here to see the equipment for 10-20TPD Small Scale Oil Refinery >>

Rice Bran Oil Extraction Worhshop View:

Rice bran is by-product obtained during rice milling operation. This is golden reddish cuticle obtained after removal of the husk and during polishing of the rice.

Rice Bran and Its Structure

Manufacturing Process of Rice Bran Oil Project:

Generally speaking rice bran oil can be extracted by chemical solvents, or pressed directly from rice bran. Here we recommend small capacity rice bran oil projects can choose expelling pressing method, while large capacity take the solvent making technique. We have to mention that hot extraction method which would get more oil yield and purer edible oil than the cold pressing method. When refers to rice bran oil production, the following three processing steps can not be ignored, they are raw material preparation, rice bran oil extraction and crude oil refining.

Rice Bran Oil Extraction: You can extract the crude rice bran oil either by mechanical method with oil presses or by chemical method with solvent. After proper preparation, the bran is fully stabilized and sent to an extraction area where oil is removed, yielding two products,a high quality crude rice bran oil and defatted rice bran.

Steam distillation is the final step in the edible oil process and it is here that any off flavors and residual free fatty acids left in the oil are removed. Once the oil has been fully processed, it is ready for packaging into retail bottles, food service pails or bulk drums. Click here to see the equipment for 10-20TPD Small Scale Oil Refinery >>

Rice Bran Oil Project:

At KMEC, we offer best solution to all of our client rice bran oil mill project. With stringent quality measures, we assure to deliver the best and perfect rice bran oil production and refinery machinery. Our products are highly durable and cost-effective for the extraction of both edible and non-edible oil. They ensure higher production output without any interval. Design is such that the oil extraction plant is easy to handle and that nearly all oilseeds and nuts may be processed. The production capacity of the expeller varies from 3 tons to 100 tons per day.Rice Bran Oil Extraction Worhshop View:

Rice Bran Oil Refining Worhshop View:

Build your rice bran oil project and make big money for your own.For any question or information on the oil expeller plant, feel free to contact KMEC- Experts in Rice Bran Oil ProjectProducts

Projects

Recent Posts

mini mustard oil mill

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Want to set up a mini mustard oil mill of your own ? With the rapid ...

mustard oil manufacturing process

Mustards are part of the oilseed family and are regarded both as a s...

Mustards are part of the oilseed family and are regarded both as a s...

small size corn oil extraction plant

Interested in begin a small size corn oil extraction plant but dont ...

Interested in begin a small size corn oil extraction plant but dont ...

rice bran oil project

Do you want to make the edible rice bran oil at from using your mill...

Do you want to make the edible rice bran oil at from using your mill...