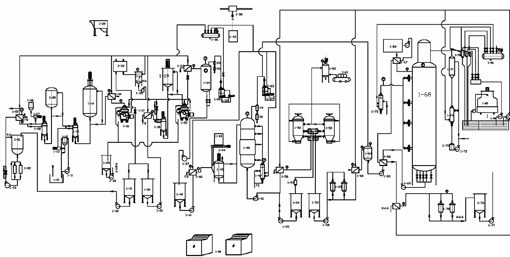

Edible Oil Refinery Process

Our edible oil refinery process system is specially designed to produce an odorless, bland, and stable oil with the appropriate color for a wide variety of cooking and baking applications. From low-cost production of bulk commodity salad and cooking oils to development of the most sophisticated designer-type oils and fats system, KMEC provides the processor with the latest technology and lowest operation costs.

Edible Oil Refinery Process

Generylly speaking, there are three main process in the edible oil refining process, they are as follows:

1. Edible Oil Refinery Process - Oil Neutralizing: Oil neutralization is also known as oil deacidfication. Since there are many kinds of oilseeds and the oilseeds quality is different from each other, we combine the merits of many technologies and develop the versatile oil neutralization washing technology. The technology can be used to process oil of various kinds, quality and requirements. Add into alkali, water and acid to remove FFA, crude phospholipids and moisture. As a result, (degummed and neutralized) oil and by-products such as soap foot, crude phospholipids, and water are obtained.

2. Edible Oil Refinery Process - Oil Bleaching:The neutralized oil is treated with bleaching earth/activated carbon for removal of colouring pigments. The bleaching agent is filtered out in vertical pressure leaf filters. Troika design ensures uniform consistency in colour with minimum requirement of bleaching agent. The bleaching line is versatile and adoptable for all varieties of vegetable oils.

3. Edible Oil Refinery Process - Oil Deodorization: Bleached oil then goes to the filter press where bleaching earth and chemicals are separated and clean bleached oil is then drawn to deodourizer where oil is heated above 110°C through thermic fluid coils and then live steam is given to the oil from the bottom steam nozzles and temperature of oil is raised upto 200 to 220°C through thermic fluid coils. Entire process is done under high vacuum. Thus smell is removed from the oil in the deodourizer. Then it goes to cooler where water circulating coils take away heat and oil is cooled. Again it goes to second filter press where completely refined and transparent colour less oil is obtained.

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Mustards are part of the oilseed family and are regarded both as a s...

Interested in begin a small size corn oil extraction plant but dont ...

Do you want to make the edible rice bran oil at from using your mill...