cooking oil production line

Since 1990 KMEC start manufacturing and exporting technically advanced machines and also professional cooking oil production line for oil production industries. We manufacture complete range of oil mill equipments from preparation of seed to filteration and refining of the oil. Our machineries cooking oil production line can be used for seeds like cotton seed, sesame, linseed and other oil seeds.

Cooking oil consists of edible vegetable oils derived from olives, peanuts, and safflowers, to name just a few of the many plants that are used. Liquid at room temperature, cooking oils are sometimes added during the preparation of processed foods. They are also used to fry foods and to make salad dressing.

Cooking Oil Production Line

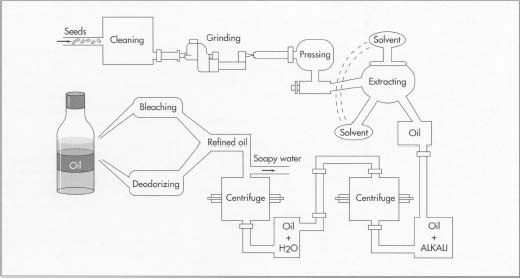

Cooking oil manufacturing involves cleaning the seeds, grinding them, pressing, and extrading the oil from them.

Cleaning and Grinding

The first process in the cooking oil production line is clening and grinding. Incoming oil seeds are passed over magnets to remove any trace metal before being dehulled, deskinned, or otherwise stripped of all extraneous material. The stripped seeds or nuts are then ground into coarse meal to provide more surface area to be pressed. The meal is then heated to facilitate the extraction of the oil.

Cooking Oil Pressing

The next process in the entire cooking oil production line is pressing. The heated meal is then fed continuously into a screw press, which increases the pressure progressively as the meal passes through a slotted barrel. Pressure generally increases from 68,950 to 20,6850 kilopascals as the oil is squeezed out from the slots in the barrel, where it can be recovered.

Extracting Additional Oil With Solvents

The next process of cooking oil production line is solvent extraction. Soybeans are usually not pressed at all before solvent extraction, because they have relatively little oil, but most oil seeds with more oil are pressed and solvent-treated. After the initial oil has been recovered from the screw press, the oil cake remaining in the press is processed by solvent extraction to attain the maximum yield. The solvent percolates through the matter which is periodically dumped and replaced.

Cooking Oil Refining

The last important procedure in the cooking oil production line is oil refining. The oil is next refined to remove color, odor, and bitterness. Oils are also degummed at this time by treating them with water heated to between 188 and 206 degrees Fahrenheit (85 and 95 degrees Celsius), steam, or water with acid. Oil that will be heated (for use in cooking) is then bleached by filtering it through fuller's earth, activated carbon, or activated clays that absorb certain pigmented material from the oil. Finally, the oil is deodorized. In this process, steam is passed over hot oil in a vacuum at between 440 and 485 degrees Fahrenheit (225 and 250 degrees Celsius), thus allowing the volatile taste and odor components to distill from the oil.

By offering cooking oil production line close to the market, we understand what our customer needs to gain a competitive edge. This ability to match the products to the market requirements allows us to produce innovative, high performance machines at a reasonable price. Waiting to hear from you.

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Mustards are part of the oilseed family and are regarded both as a s...

Interested in begin a small size corn oil extraction plant but dont ...

Do you want to make the edible rice bran oil at from using your mill...