cotton seed oil manufacturing process

Cotton Seed Oil Manufacturing Process

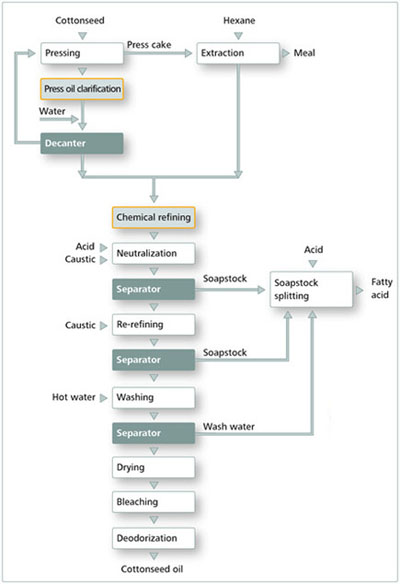

Generally speaking, the entire cotton seed oil manufacturing process includes several processes. Firstly, cotton seeds will be sent into the shaker room to be cleaned, the cleaned cotton is then sent through the grin sand where linter's are removed from the cotton seed. The next step is passing cotton seeds through hullers, where the tough seed coats are removed. The seeds obtained from this section is crushed in oil expeller presses for partial recovery of oil. The residual oil contained in the expeller cake is recovered through solvent extraction process. The oil so obtained are washed and refined in order to obtain edible cottonseed oil. All these processes are seamlessly integrated for smooth operations.

An Overview about Cotton Seed Oil

Below are some of useful infomation of cottonseed and cotton seed oil, it will be very useful for you to get a deeper understanding of cotton seed oil manufacturing process.

Cottonseed oil is a cooking oil extracted from the seeds of cotton plant of various species, mainly Gossypium hirsutum and Gossypium herbaceum. Cotton grown for oil extraction is one of the big four genetically modified crops grown around the world, next to soy, corn, and rapeseed (canola), mostly Monsanto products. Once processed, cottonseed oil has a mild taste and appears generally clear with a light golden color, the amount of color depending on the amount of refining. Cottonseed oil has a relatively high smoke point as a frying medium. Like other long-chain fatty acid oils, cottonseed oil has a smoke point of about 450 °F (232 °C). Cottonseed oil is high in tocopherols which also contribute its stability giving products that contain it a long shelf life, hence manufacturers' proclivity to use it in packaged goods.

Contact us anytime if you are interested in cotton seed oil manufacturing process, we are always at your servic!

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Mustards are part of the oilseed family and are regarded both as a s...

Interested in begin a small size corn oil extraction plant but dont ...

Do you want to make the edible rice bran oil at from using your mill...