edible oil manufacturing

Home > Recent Posts >

How the Edible Oil Manufacturing Procedure Goes

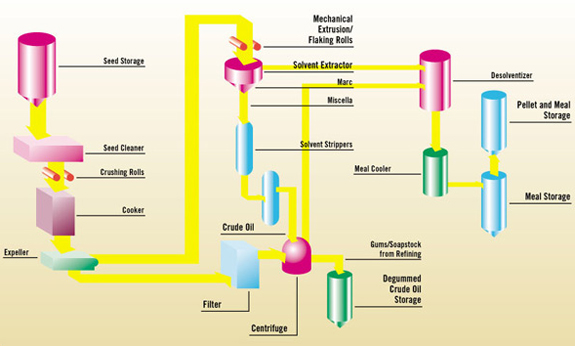

It is a complex process but it can be broken down to the following steps:Oil seed pretreatment manufacturing stage

Edible oil manufacturing process starts from the cleaning of seeds- the raw materials. Generally known as oil seed pretreatment, it is the first stage of the edible oil making process. The seeds are passed through a machine to remove all the impurities like the outer covering, the chemical fibers, seeds and leaves. In addition, still in this step, a magnet is passed through the seeds to remove any metal particles that might be present.

Oil pressing manufacturing stage

Oil pressing manufacturing stageThe second stage is the oil pressing. This stage follows the preparation of the seeds through grinding and crushing thus forming a paste. This stage is the core of the entire manufacturing process. It determines the quality of results and ought to be tackled with uttermost care. It is divided into several sections. They include the pretreatment section, cooking section, pressing section, and lastly filtering of the oil section.

Solvent extraction stage

The type of the seed used matters a lot during this stage. The cold pressed seeds give pure oil while others requires additional stages for the oil produced to be edible. With the first type, this stage sucks the oil directly from the raw materials producing edible oils. With the latter, purification is needed and it becomes the last stage of the edible oil manufacturing process.

It is during this stage that all the impurities are removed. The possible impurities present include the coloring matter, phospholipids, waxes, gums, fatty acids and other impurities that could endanger the lives of the users. Then the edible oil is packed to clean containers and sealed using a sealing machine.

Products

Projects

Recent Posts

mini mustard oil mill

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Want to set up a mini mustard oil mill of your own ? With the rapid ...

mustard oil manufacturing process

Mustards are part of the oilseed family and are regarded both as a s...

Mustards are part of the oilseed family and are regarded both as a s...

small size corn oil extraction plant

Interested in begin a small size corn oil extraction plant but dont ...

Interested in begin a small size corn oil extraction plant but dont ...

rice bran oil project

Do you want to make the edible rice bran oil at from using your mill...

Do you want to make the edible rice bran oil at from using your mill...