palm oil extraction

Home > Recent Posts >

Palm oil extraction is reasonable for either the small-scale or the large-scale production. Whether using the modern or traditional extracting process, there must be some pros and cons here and there. It is by carrying a thorough assessment that we can know where or how to classify the extraction of palm oil. The assessment deals with things like the quality product that the process delivers, the time used and other factors. Let us outline all the facts for the extraction process of palm oil.

Extraction is suitable regardless of the scale produced, whether large scale or small-scale production. In the extraction, there is no need for a source of power because the palm oil factories create their own power. The power comes from the waste products burnings like the fiber and fruits remain. The boiler releases steam through a steam turbine that results to the production of electricity. Palm oil factories are mostly located far away from populated areas. The factories treat their own water for use.

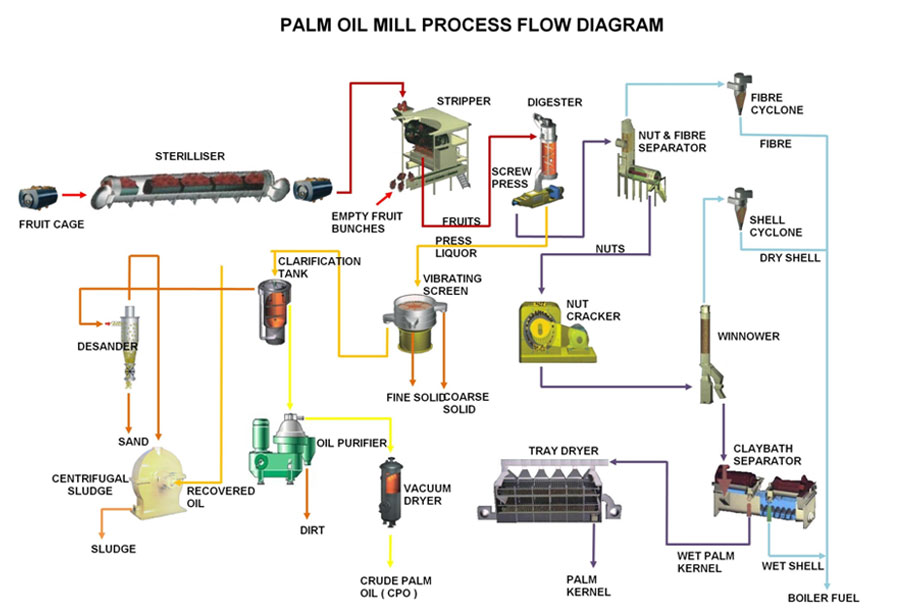

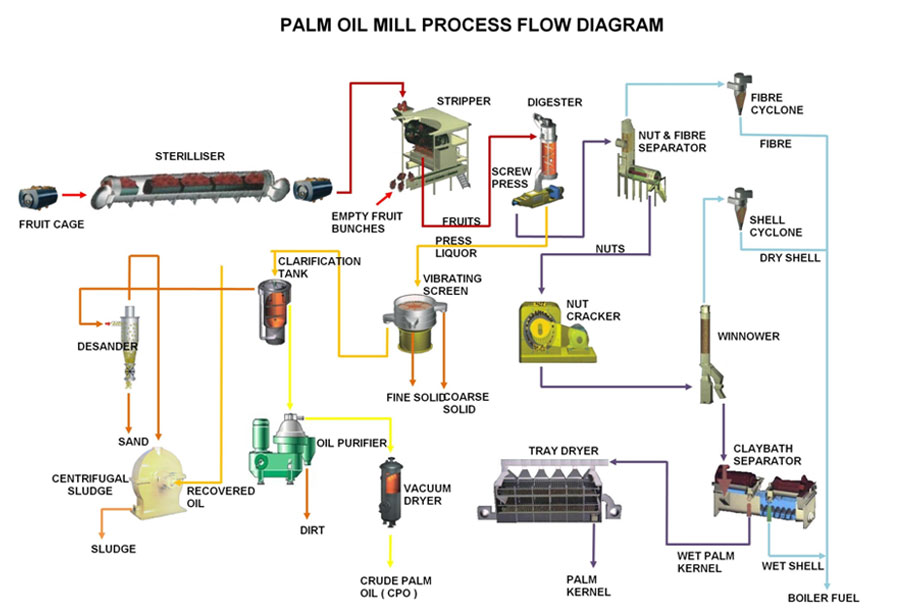

Palm oil extraction process consists of several steps. It includes the harvesting of the palm fruits stage, the Fruit reception stage, the sterilization stage, the threshing stage, pressing stage, Clarification station stage, Press cake processing stage, nut processing stage, power generation stage, Water treatment stage and lastly the Effluent treatment stage, all these stages are carried out to ensure that quality palm oil is extracted.

For small-scale palm oil production, it is possible to use the hard oil press machine while for large-scale production, the right oil press machinery will used. In any case, the stages mentioned above are followed systematically.

Is there any other shorter extraction process? Well no, the extraction process of palm oil is very long and no step can be skipped without affecting the final product.

Extraction is suitable regardless of the scale produced, whether large scale or small-scale production. In the extraction, there is no need for a source of power because the palm oil factories create their own power. The power comes from the waste products burnings like the fiber and fruits remain. The boiler releases steam through a steam turbine that results to the production of electricity. Palm oil factories are mostly located far away from populated areas. The factories treat their own water for use.

For small-scale palm oil production, it is possible to use the hard oil press machine while for large-scale production, the right oil press machinery will used. In any case, the stages mentioned above are followed systematically.

Is there any other shorter extraction process? Well no, the extraction process of palm oil is very long and no step can be skipped without affecting the final product.

Products

Projects

Recent Posts

mini mustard oil mill

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Want to set up a mini mustard oil mill of your own ? With the rapid ...

mustard oil manufacturing process

Mustards are part of the oilseed family and are regarded both as a s...

Mustards are part of the oilseed family and are regarded both as a s...

small size corn oil extraction plant

Interested in begin a small size corn oil extraction plant but dont ...

Interested in begin a small size corn oil extraction plant but dont ...

rice bran oil project

Do you want to make the edible rice bran oil at from using your mill...

Do you want to make the edible rice bran oil at from using your mill...