palm oil processing

We are expert in the field of palm oil processing. We have rich experience of manufacturing and exporting large selection of various palm oil processing machinery for different using purposes. We give the best service and we offer the most competitive prices in this filed.

Palm Oil Processing

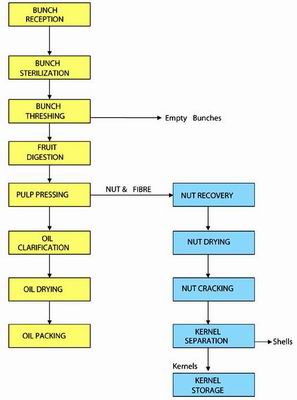

Palm oil processing starts with the harvesting of fresh fruit bunches (FFBs) which are milled within 24 hours from harvesting.

After the steaming process, the palm fruitlets are crushed in pressing machine to obtain crude palm oil and palm kernel. Waste and water is then cleared and separated from the CPO by means of a centrifuge. The cleared crude palm oil emerging from the centrifuge is then sent for refining while the palm kernel nut is sent for crushing. The empty fruit bunches and liquid waste arising from the process are used as fertiliser in the plantations.

The palm kernel is further crushed to produce crude palm kernel oil and the remaining palm kernel meal is used as animal feed.

If you want to produce refined oil in palm oil processing, crude palm oil and crude palm kernel oil is processed through three refining stages, namely degumming, bleaching and deodorising.

In the processing of degumming, the gum and fatty acid in crude palm oil and crude palm kernel oil are separated together with other impurities such as trace minerals, copper and iron by the application of phosphoric acid. In bleaching, the oil is mixed with bleaching earth (bentonite calcium) in a vacuum room to remove impurities and colour pigments in the palm oil. In deodorising, the odour and taste of the oil is removed when the oil is steamed at high temperatures between 240°C to 260°C and then cooled to room temperature.

If you prefer to know more info about palm oil processing or any other oil processing equipment, please don't hesitate to contact us, we are always at your service!

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Mustards are part of the oilseed family and are regarded both as a s...

Interested in begin a small size corn oil extraction plant but dont ...

Do you want to make the edible rice bran oil at from using your mill...