rice bran oil manufacturing process

Rice Bran Oil Manufacturing Process

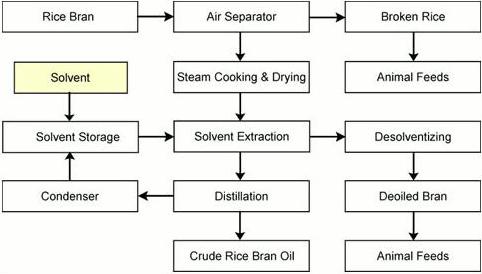

Rice bran oil manufacturing process is a complicated oil processing process, like other oil bearing materials, before making oil from rice husk, these rawmaterials should have been fully prepared. Rice bran is first screened and then heated by steam at temperature higher than 100 degrees Celsius to stop Lipase hydrolysis in rice bran prior to extraction.

You can extract the crude rice bran oil either by mechanical method with oil presses or by chemical method with solvent.The Crude Rice Bran Oil is forwarded to the refining process for purifying and packing. The extraction section is the most important section in the whole rice bran oil manufacturing process.

The refining process begins by reducing excess free fatty acid and then decreasing the colour with activated clay. After decreasing colour, the oil is forwarded to the crystallization process before filtering the wax through a filter press machine. The next process is to remove odor by using high-pressure steam deodorizer at a temperature of 230-240 degrees Celsius. The heating medium used in this process is high pressure steam. No thermal oil or PCB (Polychlorinated Biphenyl) involved in the production process at all. The result is a high quality and safe rice bran oil.

Want to start rice bran oil oil manufacturing business? Want to get the professional rice bran oil manufacturing process? Please don't hesitate to contact to et mre info, we are always at your service!

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Mustards are part of the oilseed family and are regarded both as a s...

Interested in begin a small size corn oil extraction plant but dont ...

Do you want to make the edible rice bran oil at from using your mill...